You have successfully logged out.

Excellence in Manufacturing: Discover China's Premier Suture Needles for Global Healthcare

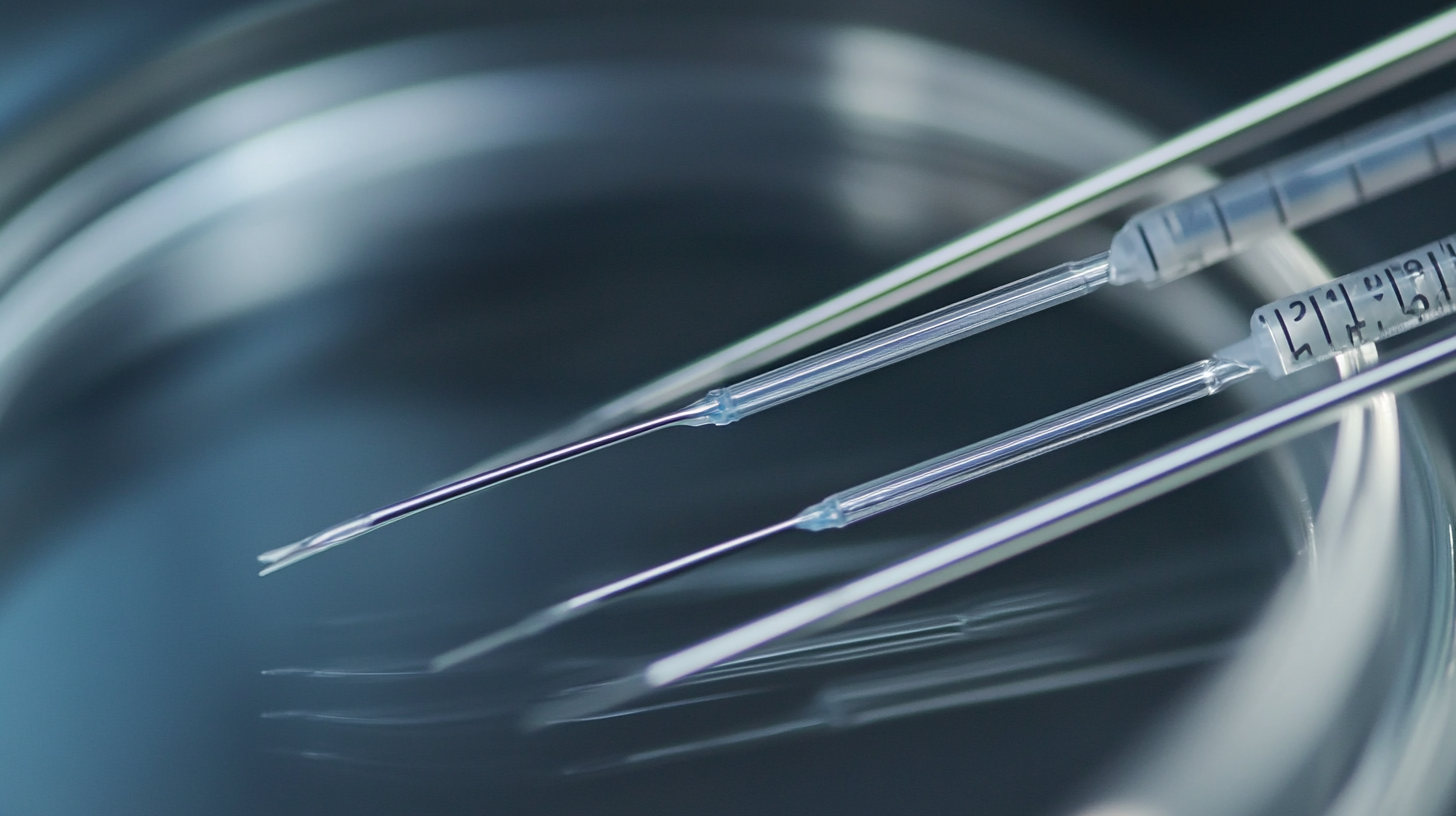

In the rapidly evolving landscape of global healthcare, the importance of quality medical instruments cannot be overstated. Among these, suture needles play a critical role in surgical procedures, impacting patient outcomes and recovery times. According to a recent report by Grand View Research, the global suture market is projected to reach $6.3 billion by 2025, driven by the rising prevalence of chronic diseases and an increasing number of surgical procedures worldwide. China has emerged as a leader in the manufacturing of suture needles, combining cutting-edge technology with high-quality materials to produce instruments that meet international standards. This blog highlights the excellence in manufacturing that characterizes China’s premier suture needles, showcasing the nation's commitment to improving healthcare while proudly exporting these essential tools to the global market.

The Evolution of Suture Needle Technology in China

The evolution of suture needle technology in China has been nothing short of remarkable. Historically, traditional suturing methods posed significant challenges, ranging from the selection of materials to the precision required for different medical procedures. Over the decades, Chinese manufacturers have embraced innovative techniques and cutting-edge materials, leading to the creation of suture needles that not only meet but often exceed international standards. This advancement has enabled healthcare professionals worldwide to achieve better outcomes in surgeries and wound care.

In recent years, the integration of digital technologies and automation in the production process has further enhanced the quality and efficiency of suture needle manufacturing. High-precision robotics and advanced quality control systems ensure that each needle is crafted with meticulous attention to detail, minimizing defects and increasing reliability. Research and development continue to play a pivotal role, with ongoing efforts to create needles that are not only more effective but also more comfortable for patients. As China's suture needle technology continues to evolve, it promises to significantly impact global healthcare, improving surgical practices and patient care across diverse medical fields.

Excellence in Manufacturing: Discover China's Premier Suture Needles for Global Healthcare

| Suture Needle Type | Material | Size (mm) | Use Case | Manufacturing Process | Sterilization Method |

|---|---|---|---|---|---|

| Cutting Needle | Stainless Steel | 30 | Dermatology | Electropolishing | Gamma Irradiation |

| Taper Point Needle | Carbon Steel | 23 | General Surgery | CNC Machining | Ethylene Oxide |

| Reverse Cutting Needle | Titanium Alloy | 20 | Ophthalmic Surgery | Laser Cutting | Steam Sterilization |

| Blunt Tipped Needle | Stainless Steel | 15 | Pediatric Surgery | Hot Forging | Radiation Sterilization |

| Curan Needle | Hypoallergenic Metal | 18 | Cardiothoracic Surgery | Precision Grinding | Plasma Sterilization |

Key Advantages of Using High-Quality Suture Needles for Surgical Procedures

As the global healthcare landscape evolves, the importance of high-quality surgical tools, such as suture needles, cannot be overstated. Recent advancements in minimally invasive techniques, particularly in orthopedic procedures, highlight a critical shift towards precision and efficacy. According to industry reports, the demand for high-quality suture needles is surging, as they are integral to the success of advanced techniques like the all-inside suturing method for treating meniscus tears, which enhances recovery time and reduces complications in patients.

Moreover, investment in innovative manufacturing within China is further driving the production of superior suture needles. The recent funding rounds for medical technology companies underscore the commitment to developing original technologies, ensuring that healthcare providers have access to products that meet stringent quality standards. Data from market analysis indicates that the market for surgical sutures is projected to grow significantly—by approximately 6.5% annually—due to the increasing prevalence of surgeries and the rising importance of suturing precision in surgical outcomes. This trend emphasizes the need for healthcare professionals to utilize high-quality suture needles to enhance surgical results and patient safety.

How Chinese Manufacturers Ensure Precision and Durability in Suture Needle Production

In the realm of healthcare, the quality of suture needles plays a critical role in surgical outcomes. Chinese manufacturers have emerged as leaders in this industry, dedicating extensive resources to ensure the precision and durability of their products. Utilizing advanced manufacturing techniques and rigorous quality control measures, these companies are transforming the quality landscape of suture needles. State-of-the-art technology and materials are employed to create needles that not only meet but exceed international standards.

A key factor contributing to the excellence of Chinese suture needles is the meticulous attention to detail in the production process. Each needle undergoes thorough testing for sharpness, strength, and flexibility. Manufacturers employ highly skilled technicians who rigorously monitor each step, from raw material selection to the final packaging. This dedication to craftsmanship ensures that healthcare providers receive reliable and effective tools for their surgical needs. Moreover, China’s commitment to research and innovation allows for continuous improvement and the introduction of new designs that cater to the evolving requirements of modern medicine.

Global Healthcare Impact: Affordable and Reliable Suture Solutions from China

In the realm of global healthcare, the demand for affordable and reliable medical supplies is ever-increasing. China's suture needle manufacturing industry stands out by providing essential solutions that meet the diverse needs of healthcare providers worldwide. These products are not only cost-effective but also adhere to international quality standards, ensuring that they can be utilized in both routine and complex surgical procedures.

The premier suture needles from China are forged through cutting-edge technology and rigorous quality control processes. Innovations in manufacturing have allowed companies to streamline production while maintaining high performance and durability in their products. This commitment to excellence not only enhances patient outcomes but also supports healthcare systems struggling with budget constraints, making advanced medical solutions accessible to a broader audience. By focusing on both affordability and reliability, Chinese manufacturers are making a significant impact on global healthcare, ultimately elevating standards of care across various medical disciplines.

Excellence in Manufacturing: Discover China's Premier Suture Needles

This chart illustrates the global market share of various types of suture needles produced in China, highlighting their affordability and reliability in global healthcare.

Suture Needle Types: Tailoring Solutions for Diverse Surgical Needs and Applications

In the realm of surgical procedures, the choice of suture needle plays a critical role in achieving optimal outcomes. China's premier manufacturers have become leaders in tailoring solutions that cater to diverse surgical needs and applications. With an extensive range of suture needle types, surgeons can select the most appropriate tool for various situations, ensuring precision and reliability in every stitch.

Different surgical specialties require specific needle designs to enhance performance. For instance, curved needles are ideal for deep tissue closure, while straight needles excel in more accessible areas. Furthermore, the use of various coatings on needles, such as silicone or epoxy, can reduce friction, allowing for smoother passage through tissue. This variety not only maximizes efficiency in the operating room but also minimizes trauma to the surrounding tissues, facilitating quicker patient recovery.

As the global healthcare landscape evolves, the demand for high-quality suture needles continues to grow. By focusing on innovation and responding to the unique demands of the surgical environment, Chinese manufacturers are poised to provide healthcare professionals with exceptional tools that enhance surgical outcomes across diverse applications.